The Nikkei Business of 15 January ran a 20-page special cover feature titled “The major competition that’s shaping up for electric vehicles (EV), as seen by Dyson”. Cover stories of this length on foreign manufactures are not unheard of, but are generally limited to firms such as IBM Corp., Amazon.com, Inc., Apple Inc., and The Boeing Company, the operations of which have a direct impact on Japanese business. For a foreign firm such as Dyson Ltd. that’s still relatively new, the coverage makes for a PR coup. It was a rare acknowledgement.

Dyson employees now number 8,000—four times more than five years ago—and one employee out of three is an engineer or scientific researcher. The writer noted with admiration that Dyson’s ratio of research and development to sales is approximately 12%, considerably higher than that of Japanese firms such as Toyota Motor Corporation and Sony Corporation.

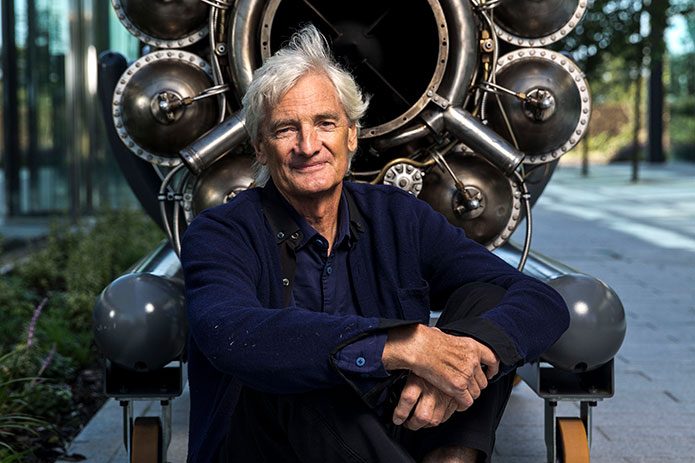

Starting with the firm’s guiding philosophy of “solving the problems others ignore”, the article introduces founder James Dyson OM CBE’s four-step innovation process, the components of which are design, build, test and break. By the time one of the firm’s much-heralded cyclone vacuum cleaners is ready for market, it will have undergone 5,000 or more cycles of this process.

Even something as mundane as a hand-held hair dryer—to cite one example—can benefit from innovative thinking, particularly considering that the existing technology in many conventional products has hardly changed in decades. In this case, many users complained that dryer operation was too slow, too noisy and damaged hair.

Harnessing aerospace technology, Dyson adopted precision rotor blades for its hair dryers that addressed the problems and harnessed customer feedback in terms of temperature settings, blower power, body colour and other features. The models are being sold in 75 countries.

Shortly after joining the firm as an engineer in 2013, Fred Howe, a graduate of the University of Leeds, proposed an idea and was quickly given research funding of £30,000.

“Working here is an engineer’s dream”, says Yvonne Tan, manager of the motor engineering section at Dyson in Singapore. But the firm won’t give the go-ahead merely with a set of blueprints. “We won’t get approval without building a mock-up and proving it will function”, explained Christopher Vincent, another developer at the firm.

On 26 September last year, company founder Dyson announced his intention to develop an EV in an open letter to his employees. Now that Dyson has thrown down the gauntlet to the EV industry. Nikkei Business is not beyond speculating that it may eventually surpass Tesla, Inc.

One key reason is the difference in corporate management. Tesla has assembled its capital through the issue of common stock or corporate bonds to investors, which it used for the development and production of its EVs, battery factory and so on. As it is heavily committed to these investors, it puts heavy pressure on its employees to come up with results quickly.

Tesla’s Chief Executive Officer Elon Musk can be described as an innovator according to the archetypal Silicon Valley formula.

Dyson, meanwhile, is privately owned and, as its EV development is self-financed, it is under no pressure to show results. The development method takes an approach similar to that of other Dyson products, with in-house technology and heavy reliance on promising young engineers.

It appears that the strategy of these two makers of EVs may be destined to collide. There’s a strong likelihood that Dyson, with its radically different corporate values and marketing approach, will not use Tesla’s success as a role model to be followed. Rather than a large sedan with long-range capability, many market watchers are expecting Dyson’s EV to be a compact aimed at daily commuters.